Exélience, a key player in the French seed industry, has been a valued partner for many years. Their continued trust in Cimbria solutions—delivered and supported by Atrissem—demonstrates the strength of local expertise combined with global innovation. Together, we’ve enhanced seed processing capabilities across multiple sites in France, ensuring efficiency, quality, and adaptability.

A Relationship Rooted in Continuous Improvement and Innovation

Since 2012, our collaboration has been defined by a shared commitment to excellence in seed and grain processing. It began with the installation of a 15 t/h cleaning line in Auffay, France, and has steadily evolved through continuous innovation and expansion.

In 2019, two advanced 25 t/h cleaning lines were commissioned in Avesnes-les-Bapaumes, enhancing capacity and efficiency. This was followed by the addition of two new lines in Auffay—a 15 t/h and an 8 t/h—each progressively upgraded to meet evolving demands. Which were followed up by serveral key enhancements, including the integration of a Gravity Separator in 2020, the DELTA Pre-Cleaners 143 in 2021, and the SEA.CX 4T optical sorter in 2024.

These projects reflect a shared commitment to delivering high-quality products, optimizing processing efficiency, and enabling seamless transitions between different seed types.

Our most recent achievement with Exélience is the successful installation of a new cleaning line at their Vernouillet facility. This project marks another step forward in a partnership built on trust, innovation, and performance values that continue to define our collaboration.

Precision and Performance in Seed Cleaning at Exélience Vernouillet

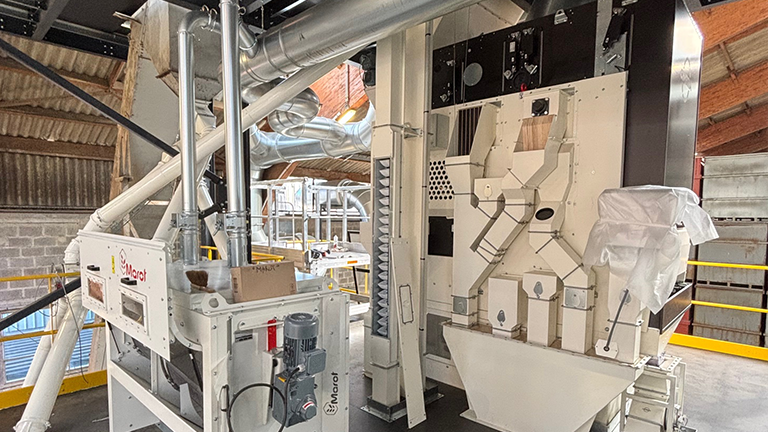

Exélience has yet again chosen Cimbria to significantly upgrade their Vernouillet facility in northern France, together with our Dealer, Atrissem. The project involved the design and implementation of a modern seed cleaning line with a capacity of 4t/h, tailored specifically for cereal, flax seeds, peas, lentils, and other seeds.

Meeting Challenges with Smart Engineering

The Vernouillet site of Exélience, located just an hour west of Paris, presented a unique challenge: integrating a new 3–4 t/h state-of-the-art seed cleaning line within their existing building while accommodating an operational paddy separator. Efficient use of limited space without compromising accessibility for cleaning and maintenance was paramount, as the facility also houses an older 10 t/h line, making space optimization a key priority.

The solution combined precision, innovation, and practicality. A special mobile platform was introduced to facilitate screen access, ensuring smooth operations. Meanwhile, the facility's layout was carefully designed to ensure ample space for operators and a streamlined workflow.

Advanced Equipment

The new cleaning line features several key pieces of Cimbria equipment:

- Delta Cleaner

Designed for high-quality cleaning with a large surface area and densiometric column, this machine ensures superior cleaning performance. Its large surface area enhances capacity while handling light seeds effectively.

- Gravity Separator

Known for its versatility, the Gravity Table refines the sorting process by consistently delivering high-quality outputs. Simple and effective adjustments further enhance operational efficiency and cleaning precision.

- Optical Sorter

This cutting-edge Sorter, it's so much more than a color sorter, equipped with color and infrared cameras, addresses persistent seed cleaning issues. It excels in detecting stones or chalk in lentils and peas, separating wheat from barley, and minimizing grain loss with a dedicated second-pass channel. - Bucket Elevators

Featuring plastic buckets and low-speed operation, these elevators were designed with easy cleaning in mind. Curved metal sheets were installed at the bottom of each elevator to simplify debris removal, contributing to hassle-free maintenance. - Chain Conveyor

This robust conveyor efficiently collects and conveys line waste, ensuring seamless processing without risk of overload, thanks to its great capacity.

Smart Design, Seamless Integration

One of the standout features of this project was the integration of an existing paddy separator into the new structure—a challenge Atriseem met with Cimbria’s expertise and precision Engineering, developing a custom mobile platform to ensure safe and easy access to the Delta cleaner’s screen, enhancing operator convenience.

The Delta Pre-Cleaner 105 screen cleaner is equipped with Cimbria’s new touchscreen interface, making it only the second of its kind in France.

The new control panel, along with Cimbria’s electrical and supervision solutions, has been praised for its ease of use and intuitive design, significantly streamlining daily operations at the plant. The equipment’s performance has consistently impressed, delivering exceptional cleaning quality that surpasses expectations. The customer has expressed great satisfaction with the results, and we are waiting for future upgrades to accommodate additional seed varieties and new market demands.

One of the plant operators shared feedback, saying, "The new control panel is incredibly intuitive and easy to use. It has made our day-to-day operations much smoother, and the performance of the equipment has been top-notch”. Additionally, the customer highlighted the cleaning quality, stating, "We are very happy with the output. The quality of cleaning exceeds our expectations, and we’re already considering future upgrades with Cimbria to handle even more seed varieties and new market opportunities”.

A Shared Vision for Future Growth

The recent commissioning of the new cleaning line at Vernouillet, expertly overseen by an Atrissem, our trusted local dealer, was delivered with precision and care, ensuring optimal performance from day one.

The Exélience team has expressed high satisfaction with both the capacity and performance of this turnkey seed processing and cleaning solution, which reflects the precision and reliability that define Cimbria’s expertise.

Encouraged by these results, Exélience is already looking ahead, exploring further enhancements to its processing lines to meet the evolving demands of the seed market. This forward-looking mindset is a hallmark of our collaboration: a shared dedication to continuous improvement, technological excellence, and long-term success.

At Cimbria, we remain committed to supporting our local partners, such as Atrissem, as they continue to grow, innovate, and lead the way in seed processing, together with market-leading clients like Exélience.

Discover more about our turnkey seed processing solutions here.