Separation of Kernels and Granular Products

Gravity Separator

Separation of Kernels and Granular Products

HIGHLIGHTS

- Used for the separation of any kind of kernel and granular product of almost identical size but with different weights.

- Utilized when the limits of air-aspiration systems and screening are reached.

- Gravity Separators are an additional piece of equipment for separating more accurately according to specific weight.

High precision separation by gravity

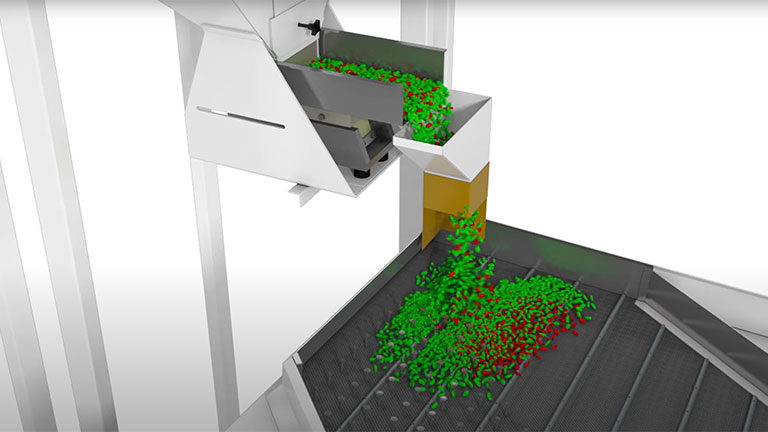

Cimbria Gravity Separators excel in separating any kind of kernel and granular product of almost identical size using weight as the differentiator. Purify your production with the right system for your operation. Eliminate stones, metals, plastics and other granular contaminants – even elements of almost identical size. The Gravity Separator builds on the principle of fluidization, by using air to separate products with different specific weights in the inclined deck. Due to the conveying system and the inclination of the deck the light material in the top layer moves down to the low side and heavy material in the bottom layer moves up to the high side of the deck.

Efficient Seperation

Our Gravity Tables ensure that every kernel is sorted with the utmost accuracy, enhancing the quality of your yield with:

Precision Separation: Cimbria Gravity Separator uses fluidization principles to separate kernels based on specific weight, ensuring high accuracy.

Versatility: Suitable for various granular products, from fine seeds to larger beans.

Efficiency: Designed to handle high volumes with minimal mixing zones, providing consistent and reliable results.

Ease of Use: Equipped with user-friendly controls and a patented eccentric drive for stability and reduced maintenance.

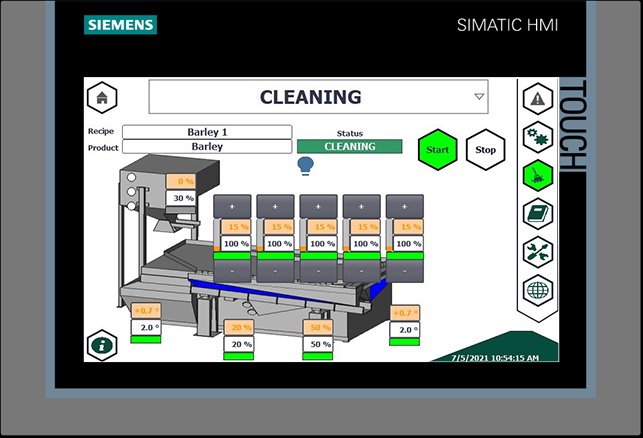

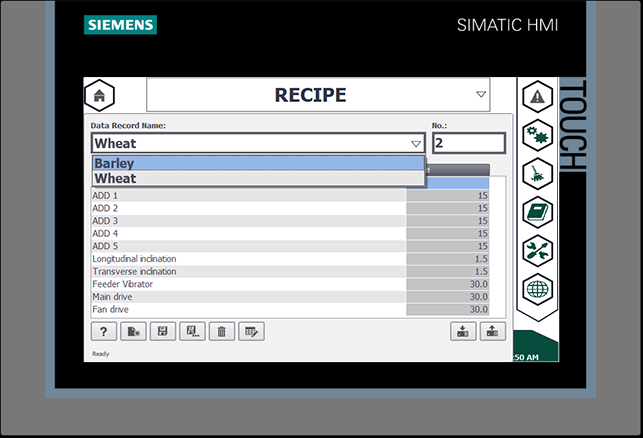

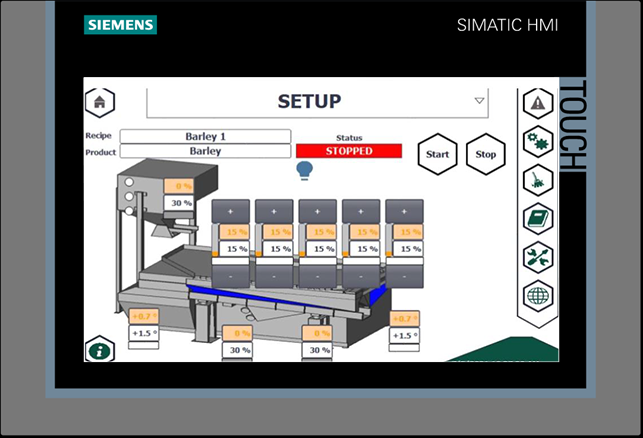

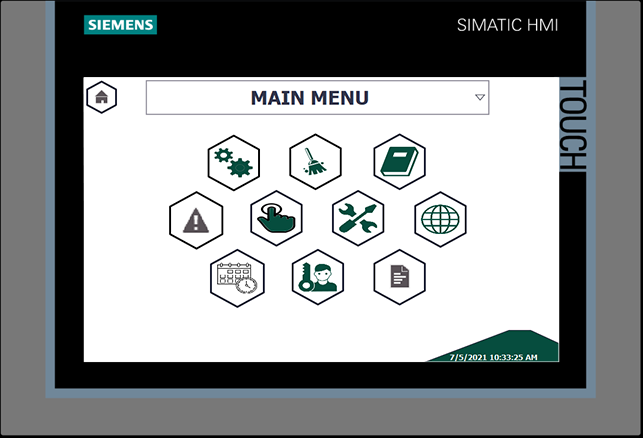

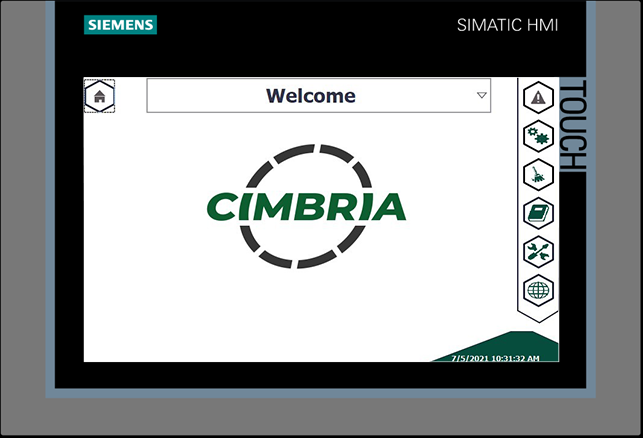

Gravity Separator’s HMI Control Panel

Experience seamless control with our Gravity Separator’s HMI panel, powered by Siemens PLC. Effortlessly manage recipes, airflow, table tilt, fan, and eccentric speed adjustments. The 9-inch LCD touch panel ensures intuitive handling of recipes, alarm notifications, and maintenance tasks.

- Recipe Control: Digitally preset for quick and easy product changes.

- Alarm Notifications: Real-time alerts for efficient monitoring and fault finding.

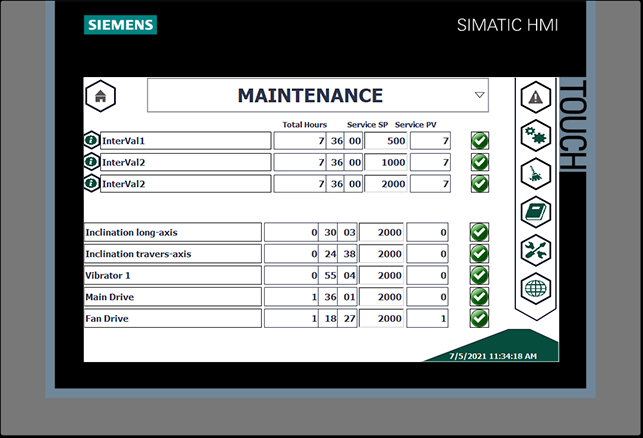

- Preventive Maintenance: Timer-based notifications to keep your equipment in top condition.

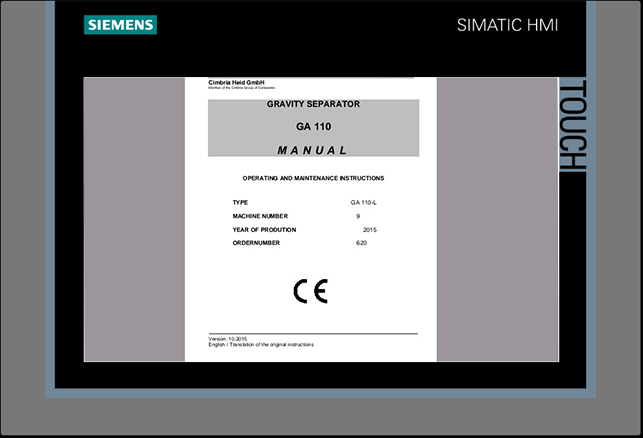

- PDF Viewer: Access user manuals, spare part lists, and maintenance notifications directly on the panel.

- OPC UA-Compatible: Seamless integration with your existing systems.

- Optional Remote Connectivity: Get expert guidance from Cimbria specialists whenever needed.

- Quick Material Change: Fast emptying feature allows for swift transitions between different materials or products.

Easy to Operate

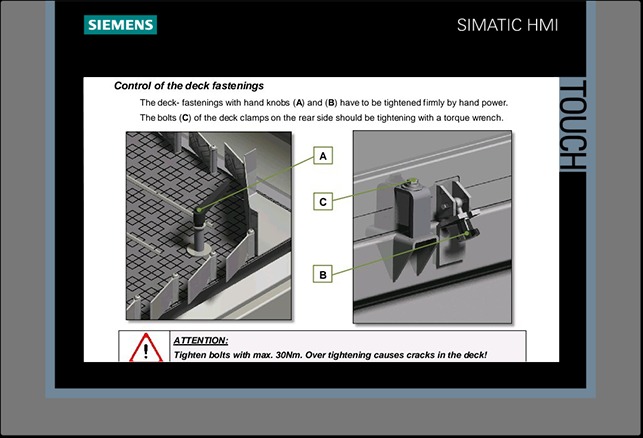

Our Gravity Separators are designed to be user-friendly. They are equipped with user-friendly controls and a patented eccentric drive for stability and reduced maintenance.

MECHANICAL CONTROL

- Adjustments are conveniently positioned at a suitable height, which enables the operator an easy and precise re-adjustment

- Each fan segment is controlled by an individual operating lever

- Deck slopes can be adjusted while the machine is running smoothly, with no locking device.

DIGITAL CONTROL

- Automatic start/stop

- Preset values for different Products (recipe-database)

- Service-management (Reminders and spare part Catalogues, user manual)

- Central control equipped With a can-bus interface Option.

Product Overview

Cimbria’s Gravity Separator is vital for corn processing.

It efficiently separates maize from stones and other crops based on weight. The Cimbria Gravity Separator uses fluidisation principles to ensure precise separation onto the conveyors.

Thinking about financing?

Get an informal talk with our financing department and learn how we can help realize your dream.

Related Articles

At Cimbria, we design, develop, manufacture and install custom-built solutions, from complete processing lines to large turnkey projects with highly advanced automation and management information systems.