Forever Plast S.p.A, a leading company in the plastic recycling industry, has recently launched an ambitious project to revolutionize the sorting and purification process of HDPE and PP flakes, using Cimbria’s world-leading optical sorting technology. With its first Cimbria optical sorter acquired 15 years ago, the Italian recycling company has maintained a pioneering position in the sector, delivering impressive results to its customers by continuing to update its machines over time.

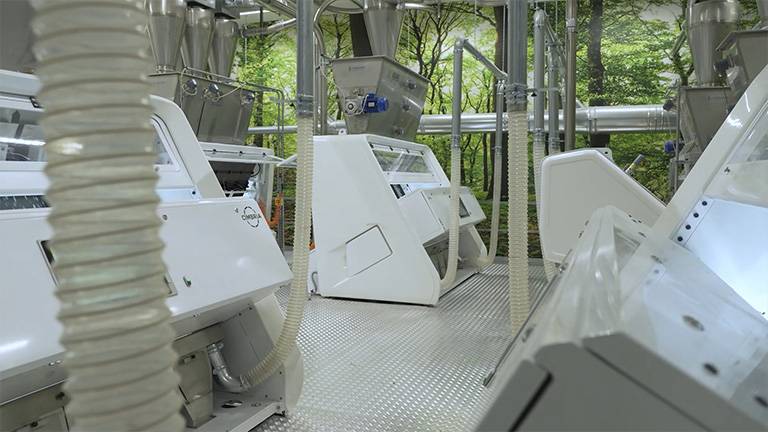

The new optical sorting line includes a combination of seven Cimbria SEA optical sorting machines to efficiently select both polymers and colors in the same processing line. Five SEA.IQ PLUS and two SEA.HY optical sorters ensure the best sorting of polyethylene from polypropylene and other polymers and the separation into different streams of color. In the sorting process the two SEA.HY are dedicated to polymer sorting, separating PP and PE with the help of the NIR/SWIR technology-equipped cameras operating in the infrared spectrum checking the chemical signature of the flakes. The additional five SEA.IQ PLUS machines are programmed to sort exclusively by color, thanks to a set of RGBN-based cameras with an advanced ability to distinguish infinitesimal shades of color.

This targeted sequence of optical sorters and the output it creates is revolutionary in the plastic recycling sector. Most of the existing plants within plastic recycling separate only neutral or white-colored flakes, allocating all the remaining objects to waste. Forever Plast’s new plant sorts all types of color, without producing any waste. In fact, there are five color streams in which SEA.IQ PLUS sorters work: neutral, white, warm colors (yellow, red, orange), cold colors (green, blue), finally black, grey, and multilayer, while it is also able to sort only one specific color. On top of that, a sixth processing stream is dedicated to the purification of polypropylene, to obtain an additional value-added fraction.

The Forever Plast plant plays an important role in the circular economy of plastic recycling being part of the circuit of materials coming mainly from Corepla plants. Corepla Plants is the national consortium in Italy taking care of collecting post-consumer bottles. In the Forever Plast plant, all the incoming material is separated into homogeneous fractions, thus enhancing the whole range of secondary raw materials. The plant has a capacity of 3 tons/hour and a high level of automation, with optimized connections to guarantee the best possible product flow for this specific process.

To ensure the optimal result, Cimbria worked closely with the customer and with the other players involved in the project in defining the best design of the sorting process, optimizing the process flow and the dedicated performance of the machines. Thanks to Cimbria’s innovative technology and know-how combined with the dedication and commitment of Forever Plast, this project ended up being a significant step forward in the recycling industry, helping maximise resources by significantly eliminating waste from plastic consumption.

Details about the machines used in the Forever Plast plant:

Cimbria SEA.HY

The Cimbria SEA.HY optical sorter represents an innovative solution for the sorting and purification of plastic materials. Thanks to its advanced technology based on infrared hyperspectral cameras, SEA.HY can identify contaminations having the same color as the compliant product, by recognizing its different chemical signatures.

This process is possible thanks to the scanning of over 300 frequencies in a range of 1000 nanometers in the infrared . Thanks to the sophisticated custom software, SEA.HY can process this data, guaranteeing maximum homogeneity and quality of the sorted materials.

SEA.HY is ideal for the recycling industry, as it excels in separating polymers having the same color, but with a different nature than the product it should be separated from. PET, PVC, PE, PP, PS, HDPE, and many more can be recovered according to the standards required by the market. SEA.HY is programmed to select flakes and granules with a very wide range of dimensions, from 1 to 30 mm, guaranteeing maximum flexibility and adaptability to specific customer needs.

Cimbria SEA.IQ PLUS

The Cimbria SEA.IQ PLUS optical sorter represents the latest solution in optical sorting technology. Thanks to its innovative integrated optical system and innovative AI powered software, SEA.IQ PLUS can sort foreign bodies and defects that the human eye would not be able to distinguish, with incomparable precision.

Its optical system is equipped with a series of RGB/NIR, SWIR and UV cameras working in multifrequency to process a variety of data from tens of thousands of scans per second. Thanks to the customization of the operating parameters, the data processing system guarantees outstanding sorting precision, aligned with the needs of each individual project.

SEA.IQ PLUS is equipped with a user-friendly interface, with increased visibility and improved graphics, which simplify the user’s operations in setting dedicated programs. The user can efficiently create programs and retrieve data remotely to optimize performance. The customizable screens allow the operator setting up the machine in accordance with the individual needs of the task, ensuring maximum operational versatility. The AI based software is taking accuracy and efficiency to a new level and allows the operator to create even the most complex recipes fast and easy.

SEA.IQ PLUS represents the maximum level of precision in optical sorting technology. Thanks to its advanced technology and the customization possibilities of the cameras, it maximizes the efficiency of the sorting process and guarantees the best quality of the sorted materials.