Safe and Clean in a Single Product

Loading Chutes

Safe and Clean in a Single Product

HIGHLIGHTS

- Designed for dust-free out-loading of dry bulk material.

- For tanker trucks, flatbed trucks, open and closed rail wagons, and containers.

- Engineered for heavy-duty performance, long-term durability and high capacity.

- Available models for virtually any dry bulk product, including agricultural, industrial commodities and raw materials.

Product Overview

CAPACITIES UP TO APPROX. 250 M³ PER HOUR

Moduflex C-Series

Basic model for loading grain, sugar, flour and similar products with moderate dust and wear characteristics.

CAPACITIES FROM 250 – 700 M³ PER HOUR

Moduflex S-Series

For loading grain, sugar, flour and similar products with moderate dust and wear characteristics.

Data Sheets

- Moduflex Loading Chute S300 Data Sheet – English

- Moduflex Loading Chute S500 Data Sheet – English

- Moduflex Loading Chute S400 Data Sheet – English

- Capacitive Indicator Data Sheet – English

- Rotating Indicator Data Sheet – English

- Flexcontrol Type V Data Sheet – English

- Flexcontrol Data Sheet – English

- Flexfill 400 Data Sheet – English

- Flexfill 300 Data Sheet – English

- Flexclose TS/TH 400 Data Sheet – English

- Flexclose TS/TH 300 Data Sheet – English

- Flexseal Data Sheet – English

CAPACITIES FROM 250 – 700 M³ PER HOUR

Moduflex H-Series

Loading chute for loading products such as cement, fly ash and similar wearing and dusty products.

Data Sheets

- Moduflex Loading Chute H300 Data Sheet – English

- Moduflex Loading Chute H400 Data Sheet – English

- Moduflex Loading Chute H500 Data Sheet – English

- Capacitive Indicator Data Sheet – English

- Rotating Indicator Data Sheet – English

- Flexcontrol Type V Data Sheet – English

- Flexcontrol Data Sheet – English

- Flexfill 400 Data Sheet – English

- Flexfill 300 Data Sheet – English

- Flexclose TS/TH 400 Data Sheet – English

- Flexclose TS/TH 300 Data Sheet – English

- Flexseal Data Sheet – English

CAPACITIES UP TO APPROX. 250 M³ PER HOUR

Moduflex F-Series

Loading chute with built-in filter module. Applications where connection to a central exhaust system is not possible or where there is a demand for the product to be returned into the product flow.

For loading of products such as grain, sugar, flour or similar products with moderate wear and dust characteristics.

Data Sheets

- Moduflex Loading Chute F300 Data Sheet – English

- Capacitive Indicator Data Sheet – English

- Rotating Indicator Data Sheet – English

- Flexcontrol Type V Data Sheet – English

- Flexcontrol Data Sheet – English

- Flexfill 400 Data Sheet – English

- Flexfill 300 Data Sheet – English

- Flexclose TS/TH 400 Data Sheet – English

- Flexclose TS/TH 300 Data Sheet – English

- Flexseal Data Sheet – English

CAPACITIES UP TO APPROX. 250 M³ PER HOUR

Moduflex D-Series

Loading chute with built-in filter module. Applications where connection to a central exhaust system is not possible or appropriate. For loading products such as cement, fly ash and similar wearing and dusty products.

Data Sheets

- Moduflex Loading Chute D300 Data Sheet – English

- Capacitive Indicator Data Sheet – English

- Rotating Indicator Data Sheet – English

- Flexcontrol Type V Data Sheet – English

- Flexcontrol Data Sheet – English

- Flexfill 400 Data Sheet – English

- Flexfill 300 Data Sheet – English

- Flexclose TS/TH 400 Data Sheet – English

- Flexclose TS/TH 300 Data Sheet – English

CAPACITIES UP TO APPROX. 440 M³ PER HOUR

Moduflex HDF-Series

Loading chute with built-in filter module in the 400 series.

Applications where connection to a central exhaust system is not possible or appropriate.

For loading products such as cement, fly ash and similar wearing and dusty products.

CAPACITIES FROM 250 – 700 M³ PER HOUR

Moduflex K-Series

Loading chute with side-mounted filter module. Applications where connection to a central exhaust system is not possible or appropriate.

For loading of products such as grain, sugar, flour or similar products with moderate wear and dust characteristics.

Data Sheets

- Moduflex Loading Chute K300 Data Sheet – English

- Moduflex Loading Chute K400 Data Sheet – English

- Moduflex Loading Chute K500 Data Sheet – English

- Capacitive Indicator Data Sheet – English

- Rotating Indicator Data Sheet – English

- Flexcontrol Type V Data Sheet – English

- Flexcontrol Data Sheet – English

- Flexfill 400 Data Sheet – English

- Flexfill 300 Data Sheet – English

- Flexclose TS/TH 400 Data Sheet – English

- Flexclose TS/TH 300 Data Sheet – English

- Flexseal Data Sheet – English

CAPACITIES FROM 250 – 700 M³ PER HOUR

Moduflex N-Series

Loading chute with side-mounted filter module.

Applications where connection to a central exhaust system is not possible or appropriate.

For loading products such as cement, fly ash and similar wearing and dusty products.

Data Sheets

- Moduflex Loading Chute N300 Data Sheet – English

- Moduflex Loading Chute N400 Data Sheet – English

- Moduflex Loading Chute N500 Data Sheet – English

- Capacitive Indicator Data Sheet – English

- Rotating Indicator Data Sheet – English

- Flexcontrol Type V Data Sheet – English

- Flexcontrol Data Sheet – English

- Flexclose TS/TH 400 Data Sheet – English

- Flexclose TS/TH 300 Data Sheet – English

- Flexseal Data Sheet – English

CAPACITIES UP TO APPROX. 150 M³ PER HOUR

Moduflex T250-Series

For loading foodstuffs and chemical products such as powder, plastic, granules.

CAPACITIES FROM 440 – 1800 M³ PER HOUR

Moduflex A-Series

The A-series is designed for loading a vast variety of dry bulk products, and where an extended length – which exceeds the capabilities of the smaller chutes in the range – is required, e.g. when stockpiling in warehouses or other open loading applications.

Data Sheets

- Moduflex Loading Chute A400 Data Sheet – English (opens in new window)

- Moduflex Loading Chute A500 Data Sheet – English (opens in new window)

- Moduflex Loading Chute A650 Data Sheet – English (opens in new window)

- Moduflex Loading Chute A800 Data Sheet – English (opens in new window)

- Rotating Indicator Data Sheet – English (opens in new window)

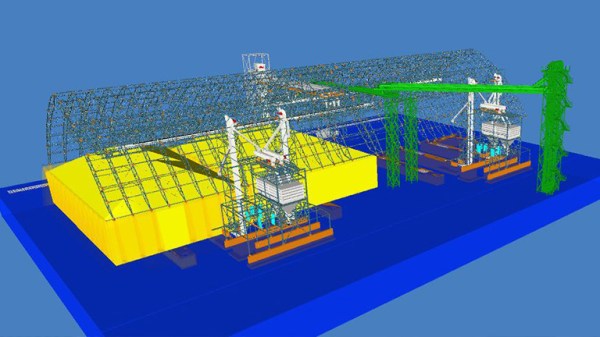

CAPACITIES FROM 250 – 3500 M³ PER HOUR

Moduflex V-Series

The loading chute V-series is designed for loading of any dry bulk materials into open and closed ships and barges, as well as for stockpiling outside and inside warehouses. The sturdy construction, including various safety functions, can accommodate an extended length up to approx. 27 m.

Data Sheets

- Moduflex Loading Chute V800F Data Sheet – English (opens in new window)

- Moduflex Loading Chute V1000F Data Sheet – English (opens in new window)

- Moduflex Loading Chute V1200F Data Sheet – English (opens in new window)

- Moduflex Loading Chute V300F Data Sheet – English (opens in new window)

- Moduflex Loading Chute V650F Data Sheet – English (opens in new window)

- Moduflex Loading Chute V400F Data Sheet – English (opens in new window)

- Moduflex Loading Chute V500F Data Sheet – English (opens in new window)

- Rotating Indicator Data Sheet – English (opens in new window)

- Flexcontrol Type V Data Sheet – English (opens in new window)

CAPACITIES FROM 250 – 1200 M³ PER HOUR

Moduflex V-Series with Integrated Filter

The V-series with integrated filter at the outlet is a series of loading chutes for loading of any dry bulk materials into open and closed ships and barges, as well as stockpiling outside and inside warehouses where connection to a central aspiration system is not possible or where there is a demand for the product to be returned into the product flow. The sturdy construction, including various safety functions, can accommodate an extended length up to approx. 27 m.

Data Sheets

- Moduflex Loading Chute V650FF Data Sheet – English (opens in new window)

- Moduflex Loading Chute V300FF Data Sheet – English (opens in new window)

- Moduflex Loading Chute V400FF Data Sheet – English (opens in new window)

- Moduflex Loading Chute V500FF Data Sheet – English (opens in new window)

- Rotating Indicator Data Sheet – English (opens in new window)

- Flexcontrol Type V Data Sheet – English (opens in new window)

FlexPositioner

Motorised positioning system for dust-free loading chute installations. Neatly engineered and compact in size.

The unit enables the outlet to be precisely positioned in any horizontal direction up to a maximum of 1000 mm from the centre point of the loading chute. The Flexpositioner can also be supplied with a beam that can be rotated through 90° to the left and to the right, thus giving 360° rotation.

Thinking about financing?

Get an informal talk with our financing department and learn how we can help realize your dream.

Related Articles

At Cimbria, we design, develop, manufacture and install custom-built solutions, from complete processing lines to large turnkey projects with highly advanced automation and management information systems.

Cimbria Port Terminal Projects in Poland Increase Customer Efficiency and Capacity

In a quite classic business as grain and seed storage and handling, two keywords are pivotal: efficiency and capacity.

Europe’s largest green coffee handling and storage plant

This contemporary plant is now able to handle different coffee batches separately and serve multiple customers at the same time.

Record-breaking order to Egypt

Cimbria has secured the biggest order in the company’s history in connection with the delivery of 23 grain silo plants to Egypt.

A significant milestone has been achieved: We have successfully delivered Moduflex No. 18,000!

At Cimbria, we are thrilled to announce a significant milestone: the sale of our 18,000th Moduflex Loading Chute! This achievement reflects the trust and confidence that our customers place in our innovative solution for dust-free dry bulk offloading.

Cimbria builds its first port silo complex in Egypt

Cimbria is increasing its presence in Egypt with a silo complex at Port Said, the Egyptian city at the entry point of the Suez Canal. The complex consists of eight silo bins with a capacity of 12,500 tons each and will be used for secure storage of wheat.

10 Years of Co-operation with TBMA België

Our collaboration with TBMA België BV dates back to 2011 and was born as an extension of our commercial relationship with TBMA Europe.