Sensationally Powerful New Fan

Reinforcing Drying Performance with CycloForce

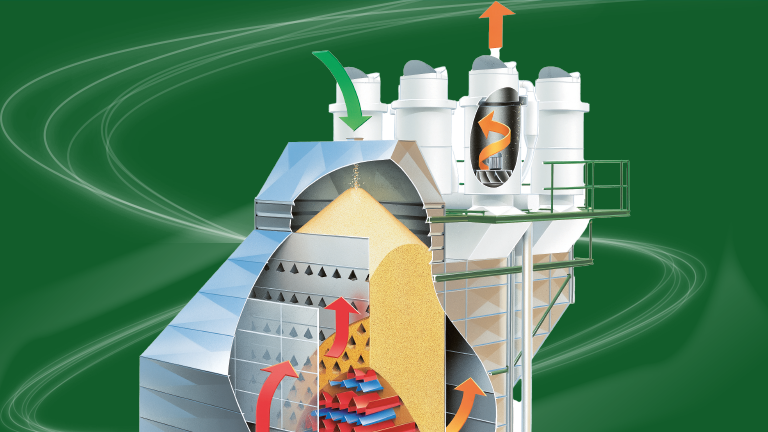

Cimbria’s Continuous Flow Dryers deliver consistent and uniform drying results for your crops such as cereal grains, maize, coffee beans, rice, soya beans, canola, etc. Your crops are gently handled along with the homogenous drying, which ensures high quality and maximized output.

With our Continuous Flow Dryers, you’ll be ensured a uniquely balance passage of airflows, temperatures, and related drying parameters resulting in optimal drying of your crops.

Experience efficient, whisper-quiet, and energy-reduced drying operations with the new CycloForce.

WHY CHOOSE THE NEW CYCLOFORCE FANS FOR YOUR A-DRYER?

Green Impact

By cutting the energy consumption, you can greatly diminish your carbon footprint and promote sustainable practices.

Double Performance

Achieve double airflow level while increasing your efficiency with a minimal cost level.

Low Operating Costs

Achieve unparalleled drying results while significantly reducing energy drying costs in daily operation.

Immediate ROI

Investment recovered in record time with guaranteed returns..

Engineered for Excellence

The popular Cimbria Cyclofan series has been expanded to include four new, ultra-powerful CycloForce models: CF1120, CF1125, CF1130, and CF1140. Each Cimbria Cyclofan uniquely integrates a fan and an efficient dust separator into a single unit. The new models uphold the exceptional dust-separation efficiency of their predecessors while achieving up to twice the airflow rate with the same installed power (kW). The airflow rate, ranges from 39 500 m³/h to 65 500 m³/h at 750 Pascal.

Adding the CycloForce fans to our Continious Flow Dryer A-series will propel your drying productivity to new heights.

- Active Dust separation: Achieve 92-98% efficiency, meeting most environmental dust emission standards for industrial grain drying facilities.

- Low noise: Features an optimized 8-blade PA rotor for high airflow rates with minimal noise and vibration, combined with an ABB IE3 High-Efficiency Motor – rotor directly mounted on the motor shaft.

- Galvanized execution: Ideal for outdoor installation and operation with humid air.

- Compact design: The Ø1120 mm fan inlet facilitates easy integration into tight spaces, maximizing efficiency without compromising performance.

- Low maintenance: Few moving parts with easily replaceable rotor, no greasing etc., ensuring high operational safety in the busy harvest season.

Thinking about financing?

Get an informal talk with our financing department and learn how we can help realize your dream.

Contact Us to Learn More About Your Savings

Want to know more about how our complete drying solutions can help you grow your business?

Fill in the form with a note about what you would like, and we will contact you with an attractive offer.