How 19 Cimbria optical sorters and one German plastics recycling facility are transforming waste into opportunity.

Plastics are everywhere. But their afterlife doesn’t have to be a waste.

We believe the real power of recycling lies in turning everyday materials back into high-quality resources, and that’s exactly what our partnership with Vogt-Plastic achieves.

Based in Rheinfelden, Germany, this family-run company has earned a reputation as one of the country’s most innovative and precise plastic recyclers. And their success comes from decades of experience and a commitment to 100% plastic recycling, transforming post-consumer plastics into high-purity, market-ready materials.

“When we first partnered with Vogt-Plastic, we recognised a shared vision,” says Alberto Zaccaria, Cimbria’s Sales Manager. “Both of our companies value precision, reliability, and sustainability — and that alignment is what makes this collaboration so powerful.”

A Shared Philosophy

Vogt’s philosophy mirrors our own. Every piece of plastic that passes through their facility is treated as a resource to be preserved and transformed, and every process is executed with uncompromising care.

Together, we combine expertise, advanced technology, and a shared vision for a circular economy, turning plastic waste into high-purity materials while setting new benchmarks for efficiency, reliability, and environmental responsibility.

Turning Philosophy into Action

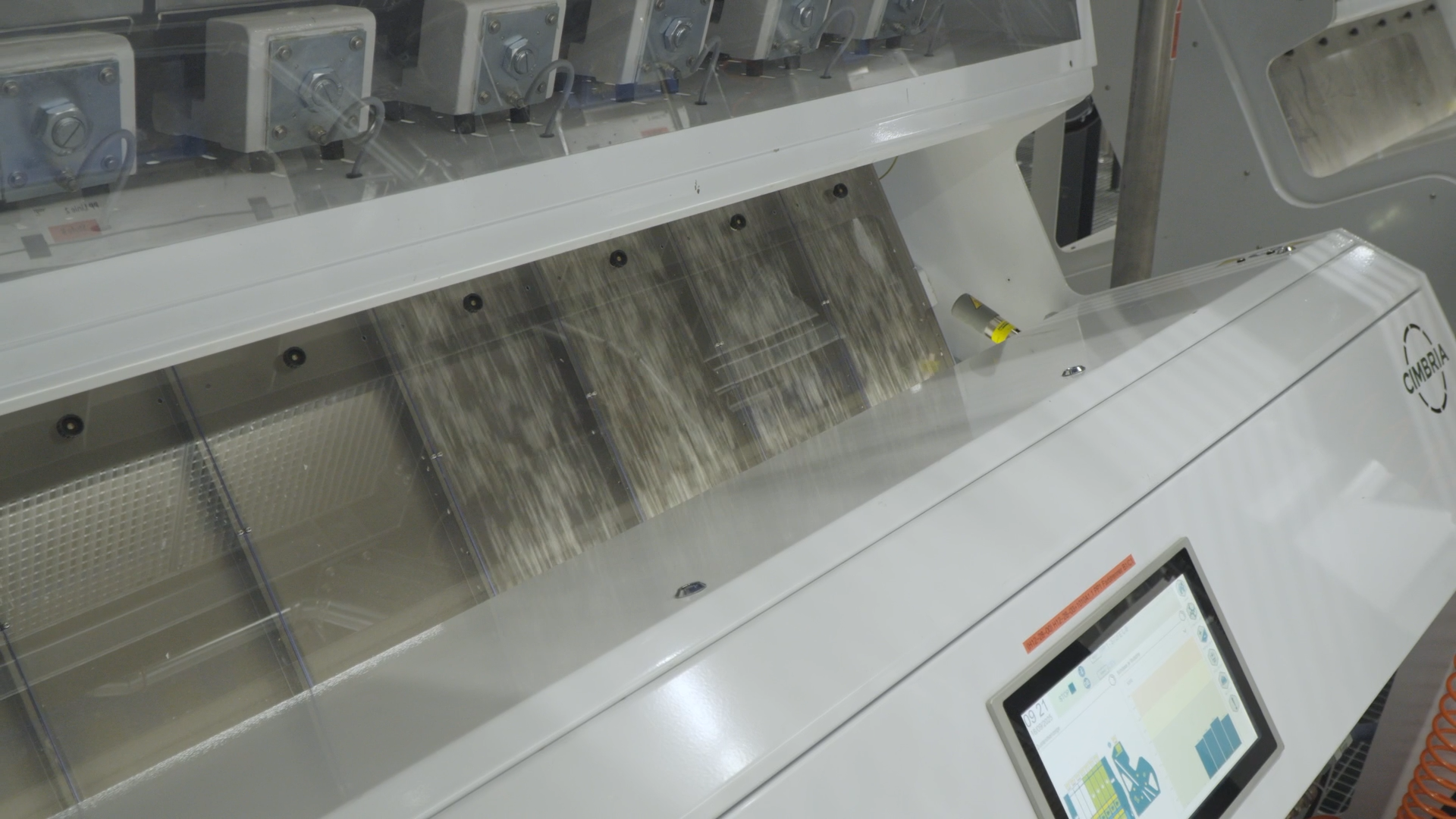

At the heart of Vogt’s facility are 19 Cimbria optical sorters, ready to handle the 200 tons of plastic the company receives each day.

The sorters are arranged across four dedicated production lines—two for high-density polyethylene (HDPE) and two for polypropylene (PP). Each one has a specific role in the workflow and are connected in series on a dedicated floor to maximise efficiency.

And thanks to their full-colour RGB sorting technology combined with NIR infrared vision, each line consistently produces either fully transparent or fully white plastics, ensuring a final product of exceptional purity. A separate optical sorter handles the most demanding separations alone, repeatedly identifying and selecting the correct plastics with remarkable accuracy.

Vogt specialists can monitor the entire process through our integrated remote control system, allowing them to oversee operations in real time, maintain optimal performance and guarantee high-quality recycling from beginning to end.

A Partnership Driving Change

By combining Vogt’s expertise in producing high-purity plastics with Cimbria’s advanced optical sorting technology, the partnership has developed a system that sets new standards for precision, reliability, and innovation.

“As partners, we’re demonstrating how collaboration can transform the way we think about recycling,” Alberto explains, continuing:

“This collaboration not only enhances the efficiency of recycling operations but also contributes to a more sustainable and resource-conscious future.”