Nestled in northern Germany, Bauck is a family-owned company with a rich history dating back to 1932. With a workforce of around 250 employees, Bauck has grown to become one of Europe’s leading producers of gluten-free organic products. Specializing in oat flakes and oat flour, the company produces over 150,000 units daily and processes more than 50,000 tons of grain annually. Bauck’s commitment to organic farming and gluten-free production has positioned it as a pioneer in the industry, and the milling facility is a marvel of automation and efficiency. Spanning nine floors and 10,000 square meters, the entire process— from truck unloading to final packaging —is contained within the building. A central control room provides a comprehensive overview of the whole operation, ensuring seamless coordination and quality control.

The Challenge: Ensuring Gluten-Free Purity

Producing gluten-free products comes with stringent legal requirements. To be certified gluten-free, products must contain less than 20 parts per million of gluten. For Bauck, maintaining this standard is critical, especially given the challenges of cross-contamination during harvesting, storage, and processing. Traditional milling equipment, while effective at removing larger impurities, could not guarantee the removal of gluten-containing kernels like wheat, barley, and rye.

The Solution: Cimbria Optical Sorters

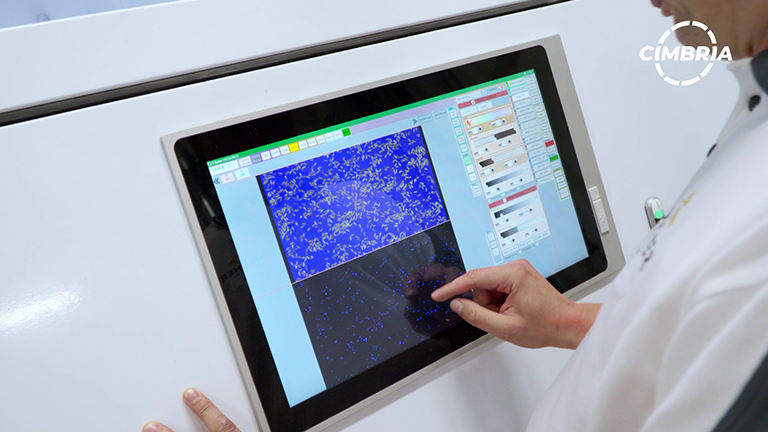

To address these challenges, Bauck turned to Cimbria’s cutting-edge optical sorting technology. After conducting trials in Italy with impressive results, our customer decided to integrate optical sorters into the production process. Cimbria’s advanced optical sorting technology helps them maintain exceptional quality standards below 5ppm, ensuring their products consistently meet strict gluten-free requirements. Today, Bauck operates three optical sorters with different tasks:

- Fine Cleaning Line: Two optical sorters, SEA.CX, equipped with RGB cameras, work in parallel to remove impurities such as rye, barley, and wheat from raw oats.

- Shelling Line: A third optical sorter, SEA.IQ Plus, equipped with double RGB full color cameras combined with Swir, InGaas, ensures the removal of unshelled kernels and double-checks the material to guarantee it’s gluten-free. SEA.IQ Plus is also equipped with BRAIN, Cimbria’s AI technology, which excels at distinguishing between shelled and unshelled kernels, even in batches with high husk content.

The Impact: Setting New Standards in Gluten-Free Production

Thanks to Cimbria’s optical sorters, Bauck has achieved a level of precision and flexibility that sets them apart in the industry. The ability to adapt to varying raw materials and impurities ensures that Bauck can consistently deliver high-quality, gluten-free products to their customers. Bauck’s dedication to innovation and quality continues to drive their success. By leveraging Cimbria’s state-of-the-art technology, they are well-equipped to meet the growing demand for gluten-free organic products while maintaining the highest standards of purity and sustainability.