Cimbria Complete™

Our process is designed with our customers at the core. From vision to reality and beyond, our team stays connected with yours.

About

Cimbria is one of the world’s leading companies within industrial processing, handling and storage of grain and seed, as well as animal feed, foodstuffs and other bulk products.

Green Coffee Processing

Adding Value from the Coffee Plant to the Roasted Bean

Green Coffee Processing

Adding Value from the Coffee Plant to the Roasted Bean

HIGHLIGHTS

- Cimbria designs and manufactures machines and equipment for green coffee processing to the highest engineering qualities and standards.

- In-depth product knowledge and expertise in the most modern processing technology and plant design ensure optimum processing of your coffee at low energy consumption.

- This guarantees that your plant and equipment will reflect the state of the art in performance efficiency and final product quality.

Green Coffee Processing Line

Video of a Cimbria Green Coffee Processing Line.

We continuously offer innovative coffee processing technology and complete turnkey solutions for coffee producers worldwide, helping reduce post-harvest loss and optimize profits.

Pacorini Silocaf

Inside Europe’s Largest Green Coffee Facility

The Pacorini Silocaf's plant in Vado Ligure, Italy, is Europe's largest green coffee handling and storage facility. This coffee handling plant was built by Cimbria with the highest level of technology in storage, conveying, cleaning, automation, and control systems. Cimbria's process ensures complete segregation of coffee batches and the highest quality in coffee management.

Coffee Optical Sorting

For the highest coffee bean quality

Cimbria’s optical sorting solutions help maximize coffee processing efficiency and profitability, allowing you to reach outstanding coffee supply chain health and security. Coffee producers big and small can benefit from our advanced optical sorter technology.

Cimbria's optical sorting equipment brings unparalleled quality and reliability to your coffee-processing business. Our optical sorters ensure the highest purity by sorting even the smallest differences in color and shape while detecting any defects and contaminants for the highest-quality coffee beans.

Product Overview

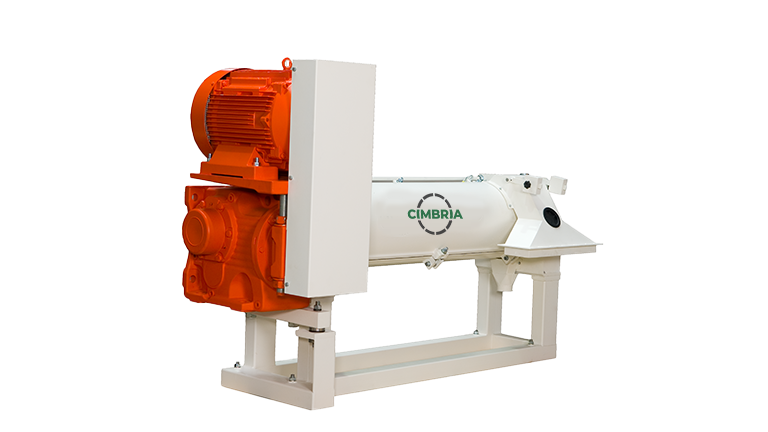

Coffee Huller SKP

The husker is designed for husking and polishing parchment coffee very gentle at a low temperatures.

The material enters the machine through the inlet, where the throughput rate is controlled by means of a slide gate.

Coffee Huller HANSA

The HANSA SM is the ideal combination of a Huller and a Polisher for treating both dry parchment and cherry coffee of any kind. Its special feature is its gentle yet complete "blunt hulling" ability, effected by the fluted broad hulling cheeks, and completed by friction under pressure of the coffee inside the cylinder. In this manner, the much acclimed polishing effect is achieved.

DELTA Screen Cleaners

The wide range of Cimbria Screen Cleaners ensures excellent efficiency and purity in the cleaning of all kinds of crops such as grain, garden seeds, grass seeds, flower seeds, corn and leguminous seeds.

Depending on the cleaning task, the Cimbria product range offers a number of screen cleaners for pre-cleaning, fine cleaning and grading. Sophisticated feeding systems guarantee uniform feeding of the screens across the entire working width.

Data Sheets

- Delta 116 Fine Cleaner Data Sheet - English

- Delta 118 Fine Cleaner Data Sheet - English

- Delta 115 Fine Cleaner Data Sheet - English

- Delta 117.1 Fine Cleaner Data Sheet - English

- Delta 112 Fine Cleaner Data Sheet - English

- Delta 114 Fine Cleaner Data Sheet - English

- Delta 118.1 Fine Cleaner Data Sheet - English

- Delta 116.1 Fine Cleaner Data Sheet - English

- Delta 117 Fine Cleaner Data Sheet - English

- Delta 142.2 Air-Screen Cleaner Data Sheet - English

- Pre Cleaner Delta 142.1

- Delta 144.1 Combi Cleaner Data Sheet - English

- Delta 146 Combi Cleaner Data Sheet - English

- Delta 143.1 Combi Cleaner Data Sheet - English

- Delta 143.2 Pre-cleaner Data Sheet - English

- Delta 138.3 Pre-cleaner Data Sheet - English

- Delta 138.2 Pre-cleaner Data Sheet - English

- Delta 132.3 Pre-cleaner Data Sheet - English

- Delta 132.2 Pre-cleaner Data Sheet - English

- Delta 132.1 Pre-cleaner Data Sheet - English

- Delta 145 Pre-cleaner Data Sheet - English

- Delta 144.2 Pre-cleaner Data Sheet - English

- Delta 138.4 Pre-cleaner Data Sheet - English

Dry Stoner

The Cimbria dry stoner is used for separating dry granular material according to specific weight into two fractions. The goal is the elimination of heavy impurities, such as stones, metallic particles and other objects from the coffee.

Gravity Separator

The gravity separator is used for the separation of any kinds of kernels and granular products of nearly the same size according to the specific weight. The size of the kernels is normally between 0.5 mm (fine seeds) and 20 mm (e.g. beans).

The product processed by the Gravity Separator is separated into layers with different specific weight according to the ”fluid bed” principle.

Data Sheets

- Gravity Separator GA 310 Data Sheet - English

- Gravity Separator LAB GA Data Sheet - English

- Gravity Separator GA 110 Data Sheet - English

- Gravity Separator GA 71 Data Sheet - English

- Feeding Device SP 6/18/24 Data Sheet - English

- Gravity Separator GA 31 Data Sheet - English

- Gravity Separator GA 210 Data Sheet - English

SEA.CX

Optical Sorting

Cimbria’s RGB Full-Colour SEA.CX offers the ultimate technology to meet the most demanding quality standards of seeds, grains, food and non-food commodities, and is recognised as being the best-performing and most reliable optical sorter on the market.

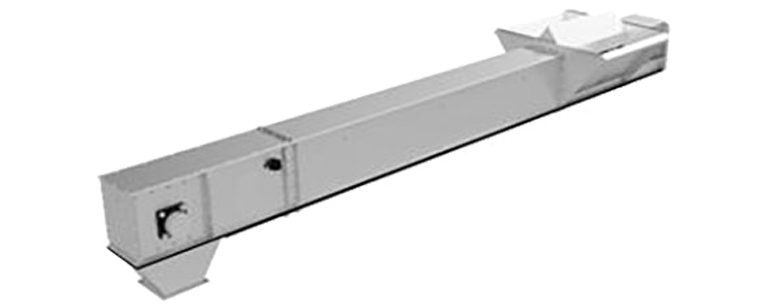

Chain Conveyor

The Cimbria chain conveyor range of products contains models constructed to suit various materials and tasks, and comes with a range of standard features.

Data Sheets

- Electronic Speed Guard Data Sheet - English

- Chain Conveyor Support System Data Sheet - English

- Chain Conveyor type RL Data Sheet - English

- Chain Conveyor type RM Data Sheet - English

- Chain Conveyor type RS Data Sheet - English

- Chain Conveyor type RW Data Sheet - English

- Conveyor Chain Data Sheet - English

- Chain Conveyor type RA Data Sheet - English

- Slide Gate RL/RS/RM Data Sheet - English

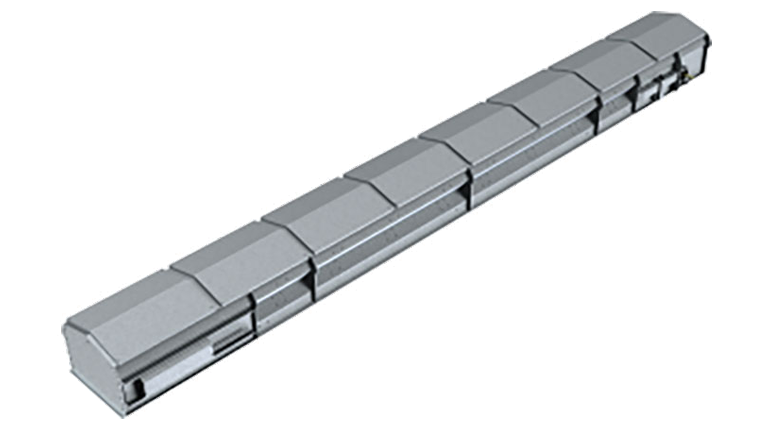

Belt Conveyor

Cimbria belt conveyors are ideal for gentle horizontal conveying of granular products such as grain, pellets, powder, etc. A Cimbria belt conveyor is totally self-emptying, whilst energy consumption and wear are minimal.

Data Sheets

- Misalignment Detector XY-81.AT2.49B Data Sheet - English

- Misalignment Detector XY-81.AT2.13 Data Sheet - English

- Support system GT GF GI GH Data Sheet - English

- Tripper for GT Belt Conveyor Data Sheet - English

- Belt Conveyor GF Data Sheet - English

- Belt Conveyor GI Data Sheet - English

- Belt Conveyor GH Data Sheet - English

- Belt Conveyor Type GT Data Sheet - English

- Misalignment Detector XY-81.AT2.41 Data Sheet - English

- Misalignment Detector XY-81.AT2.11 Data Sheet - English

Bucket Elevator

The Cimbria bucket elevator is ideal for the vertical transport of products such as grain, pellets and powder. It stands out due to its high degree of durability, safety features and low power consumption in relation to its capacity. It is highly resistant to wear and is suitable for both indoor and outdoor use.

Data Sheets

- Explosion Relief Data Sheet - English

- Electronic Speed Guard Data Sheet - English

- Bucket Elevator EE18, 20, 24 w Drive arrangement and Belt Data Sheet - English

- Bucket Elevator EC5, 6, 8 w drive arrangement and Belt Data Sheet - English

- Bucket Elevator Type EE Data Sheet - English

- Bucket Elevator Type EC Data Sheet - English

- Bucket Elevator Type EF Data Sheet - English

- Bucket Elevator Type ED + EE Data Sheet - English

- Elevator Belt Type EP Data Sheet - English

- Elevator Buckets Type EU Data Sheet - English

- Bucket Elevator Support System Data Sheet - English

- Misalignment Detector XY-81.AT2.11 Data Sheet - English

- Bucket Elevator Type EH Data Sheet - English

- Misalignment Detector XY-81.AT2.49B Data Sheet - English

Related Articles

At Cimbria, we design, develop, manufacture and install custom-built solutions, from complete processing lines to large turnkey projects with highly advanced automation and management information systems.

Precise optical sorting

Optical Sorting that delivers the results you need!

Our innovative optical sorting solutions will take your operation to the next level. With our advanced optical sorters, you can achieve unparalleled quality and reliability in your sorting process. Our optical sorters ensure great purity, optimized yield, and food safety with a smart design to deliver extreme performance.